Leather, an intrinsically circular material

Leather is at the heart of our expertise. It represents 70% of the raw materials we use to produce our leather goods and accessories. Born from the revaluation of a waste - the thousands of tons of hides generated every day by the slaughter of animals intended for meat consumption - leather is a high-performance and durable material with intrinsically circular potential.

Towards more responsible tanning

However, the processing of hides, which takes place in tanneries, consumes a large amount of water and requires the use of chemicals such as chromium to soften them.

That is why, since 2005, a non-profit organization that brings together 1300 stakeholders in the leather industry, the Leather Working Group (LWG), has been evaluating the compliance of tanneries in terms of water and energy consumption, waste management, atmospheric and noise emissions, traceability, health and safety, and the use of restricted substances.

4 out of our 5 partner tanneries are now LWG Gold (with a score of 85%) or Silver (score of 75%) certified! Moreover, all located in Europe, they comply with the European REACH regulation that governs the use of chemicals.

Since 2022, Lancaster has also been a member of the Leather Working Group.

Going further

We are working together towards obtaining LWG Gold certification for 100% of our raw material suppliers. Involved in working groups, notably with the National Leather Council, we aim to contribute to ever more sustainable tanning and to strengthen our response to major issues such as the traceability of livestock.

Trims and linings

The rest of the raw materials we acquire are trims (clasps, rivets, zippers, and pulls) and linings (suede, canvas, nylon). The processing of these materials also requires the use of chemicals, which is why we require our suppliers to guarantee their safety, both for our artisans and our customers, by complying with recognized international standards: REACH, Oeko-Tex, or GRS 4.0.

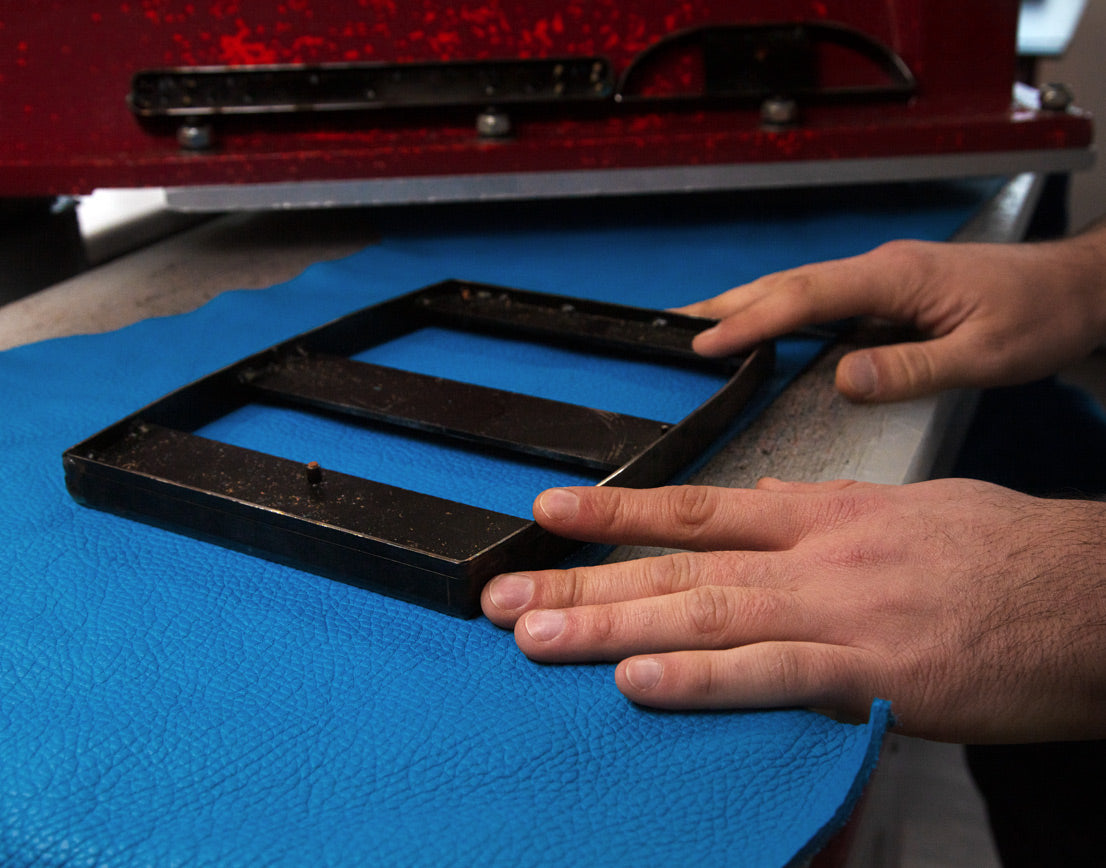

When skin transforms into leather

It is in the tannery that animal skins are chemically and mechanically treated for leather production: they are first cleaned (hair and dirt removed from their outer surface and inner skin removed) then soaked in vats containing tannin, for a certain period. The product used can have a natural origin (tannin from oak whose bark was ground in a tannery mill, or other forest species) or be a synthetic chemical product.

A 4-axis approach

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Fusce quis tellus felis. Nunc vitae neque lacus. Maecenas vehicula risus et vehicula tempor. Nam massa ipsum, molestie nec sodales faucibus, iaculis eu turpis. Nunc aliquet, diam et auctor tincidunt. View the full project report